立式恒温恒湿机组

Product Category:

Keywords:

一、产品概述

新雅恒流恒恒湿空调机是新雅公司积影多年实践经验设计而成的机组。机组采用智能化的控制模式,实现制冷、除湿、加热、加混等功能,

而达到对室内环境温、湿度的精确控制。广泛适用于电子、光学设备、仪器仪表、化妆品、胶片车间、医疗卫生、生物制药、档案馆、

物馆、图书馆、食品房、精密机械、各类计量、检测及实验室等对空气温、湿度精度要求较高的场合。

本产品执行国家标准:

DGB/T177582010 8单元式空气调节机》

②GB 19576-2001<《单元式空气调节机能效限定值及能源效率等级》

二、产品特点

1、智能控制、控制精度超高

人性化的微电脑控制系统,操作简单方便。采用PID模糊控制方案,实现温度和湿度的同步精确控制,可靠性高的PDC/PLC控制器,多驳能”调节,室内温湿度波动小,温度精度达+0.8°℃,湿度精度土5%-8%。冷热调节功能更全面、调|节更精确,性能更突出。

2、高效节能

可根据需求提供高能效水冷及风冷系列恒温恒湿机产品,能效比远超国家级节能标准,达到行业领先水平。

3、设计灵活、性价比超高

辅助加热方式(电加热,蒸汽加热、热水加热)及 送回风形式多样,便于匹配组合。升级优化的恒温恒湿机质量稳定可靠使用简单方便,性价比超高。

4、高端设计、外形美观

优化后过渡棱角体现个性化设汁,精细的加工工艺,彰显高端设计和使用空间的品位。机组结构紧凑,外形美观,便于安装、运输及维护

5、 多重保护、安全可靠。

机组设有多重安全保护,如压缩机高低压,压缩机过流、过载,电加热过热,欠风保护等,确保机组安全可靠

6、 规格众多

本系列设有10-96HP共12个规格:有风冷、水冷两种冷却方式:有前回侧送:-前回顶送、·后回顶送三种送回风方式,每种机组设有左、右丙种接管方式,并且有R22、R407C.R134à、 R410A等制冷剂供选择满足客户不同使用环境的需求。

7、非标定制

根据用户的使用特点(如:环保制冷剂、送回风方式等),可提供更人性化定制,免费设计最优的空气环境调节方案,电源形式可根据使用地造择380V~50HZ.380V~60HZ.400V~50HZ.400V~60HZ、415V~50HZ.460V~60HZ等多种形式,如果非标电源,请订货时说明。

8、 特殊处理

根据使用场合的具体要求,机组可做防爆防腐处理。可广泛用于石油、化工、冶金、军工、医药等行业存在或可能存在IA、IB、 IC级T1~T4组可燃性气体、蒸气与空气混合形成的爆炸性气体混合物的1~2区场合。

三、产品汇总表

类型/ 项目/ 压缩机匹数 ( HP ) |

10HP | 12HP | 15HP | 20HP | 24HP | 30HP | 36HP | 40HP | 48HP | 60HP | 72HP | 96HP | |||

风量 m³/h |

5600 |

6500 |

8000 |

10000 | 1 2000 |

1 4000 |

1 8000 |

20000 | 22000 |

26000 |

35000 |

45000 |

|||

系统数目 |

2 |

2 |

3 |

4 |

4 |

3 |

3 |

4 |

4 |

3 |

3 |

4 |

|||

| 水冷 | R22 |

型号 |

H28 |

H35 |

H45 |

H59 |

H70 |

H88 |

H103 |

H115 |

H135 |

H175 |

H200 |

H260 |

|

制冷量 |

KW | 28 . 2 |

35 . 2 |

44 . 6 |

58 . 7 |

69 . 7 |

88 . 4 |

1 03 . 2 |

1 1 5 |

135 |

175 |

H200 |

261 |

||

R407C |

型号 |

H28H |

H35H |

H45H |

H59H |

H70H |

H88H |

H1 03H |

H115H |

H135H |

H175H |

H200H |

H260H |

||

制冷量 |

KW |

29 . 6 |

35 . 5 |

45 . 3 |

59 . 7 |

70 . 9 |

89 . 8 |

105 |

118 |

133 |

173 |

H200 |

261 |

||

| 风冷 | R22 |

型号 |

HF 25N |

HF 31 N |

HF39N |

HF 52N |

HF62N |

HF78N |

HF92N |

HF 1 00N |

HF 120N |

HF 158N |

HF 176N |

HF 230N |

|

制冷量 |

KW |

25 . 6 |

31 |

39 . 2 |

52 . 3 |

61 . 5 |

77 . 6 |

91 . 8 |

100 | 120 |

158 |

176 |

233 |

||

R407C |

型号 |

HF 25 NH |

HF31 NH |

HF 39 NH |

HF 52 NH |

HF 62 NH |

HF 78 NH |

HF 92 NH |

HF 100 NH |

HF 120 NH |

HF 158 NH |

HF 176 N |

HF 230 NH |

||

制冷量 |

KW |

24 . 8 |

30 . 2 |

40 |

53 . 9 |

62 . 1 |

77 . 6 |

92 . 3 |

96.9 | 119 |

1 62 |

186 |

248 |

||

四、名义工况

| 室内侧状态 | 室外侧状态 | ||||

进风温度 |

风冷式进风温度 |

水冷式 |

|||

干球温度 |

湿球温度 |

干球温度 |

湿球温度 |

进水温度 |

出水温度 |

| 23℃ | 17℃ | 35℃ | 24℃ | 30℃ | 35℃ |

五、运行范围

制冷时,室内最高进风温度28 ° C, 最低进风温度18 ° C; 室外最高进风温度43 ° C ,最低进风温度18 ° C。

水冷机最高进水温度34 ° C ,最低进水温度20 ° C ,承受最高水压0.4MPa。

机组长时间在超出上述范围运行,会导致损坏,如客户确有需要,请在订货时说明。

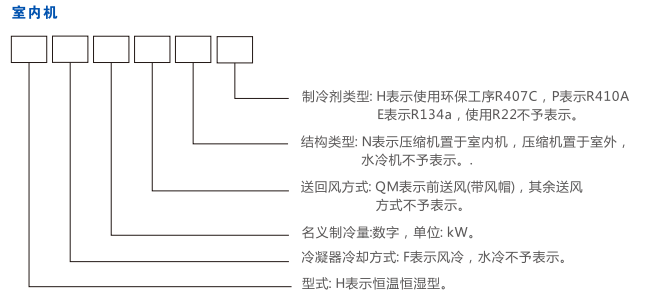

六、产品型号表示方法

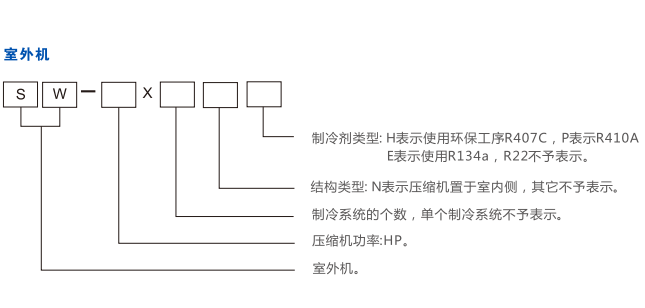

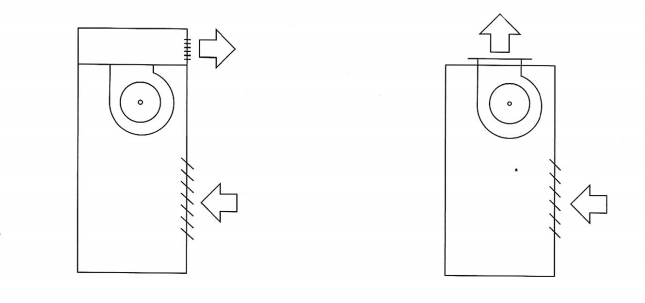

七、送回风方式

|

|

| A、前回风 , 前送风 ( 带风帽 ) 适用于10HP ~ 24HP机组 | B、前回风 , 顶送风 适用于10HP ~ 24HP机组 |

|

|

| C、后回风 , 顶送风 ( 带风帽 ) 适用于10HP … 96HP机组 |

D、空调机接上增压箱 可增加风压 ( 所有顶送风机型 ) 注 : 以上机型前回风均为直接回风不接风管 , 如需接风管请非标注明。 |

七、送回风方式

室外机

| 项目/参数/型号 | SW-5N | SW-10N | SW-(5X2)N | SW-(6X2)N | SW-(10X2)N | |

电机功率 KW |

0 . 25 |

0 . 55 |

0 . 55 |

0 . 75 |

0 . 55x2 |

|

噪音 dB (A) |

64 |

71 |

71 |

73 |

75 |

|

电源 KW |

3 ~ 380V(50 Hz ) |

|||||

连 接 管 |

气管 |

中15.9 (中19.1) |

中19.1 (中28.6) |

中15.9 (中19.1) |

中15.9 (中19.1) |

中19.1 (28 . 6) |

数量 |

1 | 1 | 2 | 2 | 2 | |

液管 |

中 12 . 7 |

中 15 . 9 |

中 12 . 7 |

中 12 . 7 |

中 15 . 88 |

|

数量 |

1 | 1 | 2 | 2 | 2 | |

连接方式 |

喇叭口螺纹连接 |

|||||

外 形 尺 寸 |

宽 mm |

760 |

820 |

820 |

922 |

819 |

深 mm |

723 |

820 |

820 |

983 |

1727 |

|

高 mm |

759 |

983 |

983 |

1155 |

982 |

|

重量 ( 净重 ) kg |

52 | 85 |

85 |

105 |

200 |

|

| 项目/参数/型号 | SW-12N | SW-20N | SW-24N | SW-(12X2)N | |

电机功率 KW |

0 . 75 |

0 . 55x2 |

0 . 75x2 |

0 . 75x2 |

|

噪音 dB (A) |

73 |

75 |

77 |

73 |

|

电源 KW |

3 ~ 380V(50 Hz ) |

||||

连 接 管 |

气管 |

中 22 . 2 (中 28 . 6 ) |

中 28 . 6 (中35) |

中 28 . 6 (中35) |

中 22 . 2 ( 中 28 . 6) |

数量 |

1 | 1 | 1 | 2 | |

液管 |

中 12 . 7 |

中 15 . 9 |

中 12 . 7 |

中 12 . 7 |

|

数量 |

1 | 1 | 1 | 2 | |

连接方式 |

喇叭口螺纹连接 |

||||

外 形 尺 寸 |

宽 mm |

922 |

819 |

819 |

819 |

深 mm |

981 |

1727 |

1727 |

1727 |

|

高 mm |

1155 |

982 |

1180 |

1180 |

|

重量 ( 净重 ) kg |

105 |

200 |

215 |

215 |

|

八、外形及空调安装尺寸

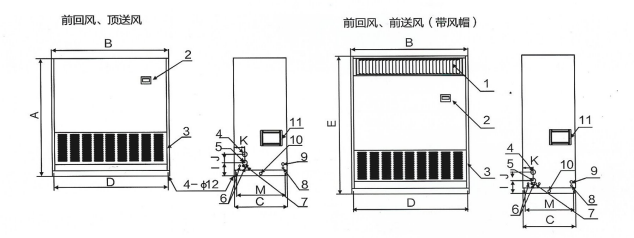

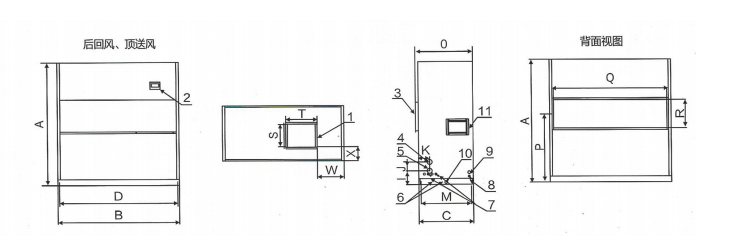

H28(H) ~ H70(H); HF 25N(H ) ~ HF 62N(H)外形示意图

注:

1、直接回风型机组可在机组侧面开设新风口,常规为左侧接管,并配备法兰。

2、对于接风管回风型机组,如果需要引入新风,建议新风口开设在回风管道上。

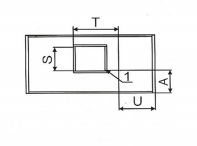

3、新风法兰的尺寸如下图示。

4、新风口及新风法兰都不是常规配置,如有需要请在定货时说明.

5、常规配置冷媒接管在左侧。如需其它方式请在订货时注明。组的重量及配管请咨询新雅公司。

6、对于采用R134a的E型机组,以上参数计咨询新雅公司

| 序号 | 名称 |

| 1 | 出风口 |

| 2 | 控制器操作面板 ) |

| 3 | 回风口 |

| 4 | 冷却水出水孔 ( 水冷机专有 ) |

| 5 | 冷却永进永孔 ( 水冷机专有 ) |

| 6 | 气管连接孔 ( 风冷机专用 ) |

| 7 | 冷却水出水孔 ( 水冷机专有 ) |

| 8 | 加湿器进水孔 (G3/4" ) |

| 9 | 电源线孔 |

| 10 | 排水孔 ( 内螺纹 G1 " ) |

| 11 | 新风法兰 |

![]()

![]()

![]()

Previous

Next

Product Inquiry

*Note: Please fill in the information accurately and keep the communication open. We will contact you as soon as possible.