热泵型风冷模块机组

Product Category:

Keywords:

一、产品设计标准

1.《 GB/T14294-2008组合式空调机组》

2.《 GB/T19569 - 2004洁净手术室用空气调节机组》

3.《 EN1886 - 2007建筑通风用空气处理机组机械性能》

二、产品标准理念

| 1.产品设计和检验严格贯彻中国国标《GB/T14294-2008组合式空调机组》《GB/T19569-2004洁净手术室用空气调节机组》 和国际标准《EN1886-2007建筑通风用空气处理机组机械性能》: 2.净化型组合式空调机组是对洁净区域空气的温度、湿度、洁净度、压差、噪音及气流速度等关键指标进行控制的最重要设备。其安全可靠性能是盾安产品设计理念的最关键因素之-;3.洁净区域空气指标的有效维持需要消耗大量的电能、热能等能源。盾安公司通过优化换热、降低流体阻力等手段有效降低了净化型组合式空调机组的能耗。同时,尽量减少二次污染,创造健康、卫生的洁净环境也是我们在设计这款产品时重点关注的因素之-:4、手动控制已经无法满足设备科学管理、动态调整的需求,智能控制已经成为洁净空调系统的基本要求,在设计产品时,既要考虑对产品本身的控制,也要兼顾到对整个净化空调系统的控制和数据储存。 |

|

三、产品检测

新雅净化型组合式空调机组经国家空调设备质量监督检验中心权威 测试,机组漏风率 、机械强度 、桥因子和传热系数等参数均处于行业 领先水平。

| 检测项目 检测结果 | |

| 漏风率 | L1 |

| 机械强度 | D1 |

| 冷桥因子 | TB1 |

| 传热系数 | T2 |

三、产品性能优势

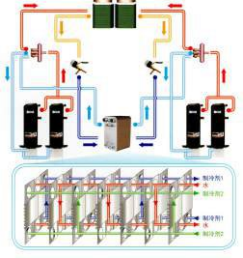

高效设计 水侧和两个制冷剂侧交叉对流换热,任一板片间水流同时与两个制冷剂系接触,保证全部水流始终参与换热,最大限度地提高单台机组部分负荷运行时的性能; |

|

全新外形设计

XYAE065X U型空气侧换热器设计: |

|

定制型风扇组件: 风扇 、电机 、导风圈 、导风罩一命式计, 风量大, 风 阻小, 换热效率高, 噪音更低; 紧凑型结构: 创新的模块机外形设计,尺寸更小巧,同冷量 机型尺寸仅为传统机组的65%, 应用灵活; |

XYAE100/130X U型空气侧换热器设计: |

定制型风扇组件:风扇、电机、导风圈、导风罩--体式设计,风量大、风阻小,换热效率高,噪音更低; 紧凑型结构:创新的模块机外形设计,尺寸更小巧,同冷量机型尺寸仅为传统机组的68%,应用灵活; |

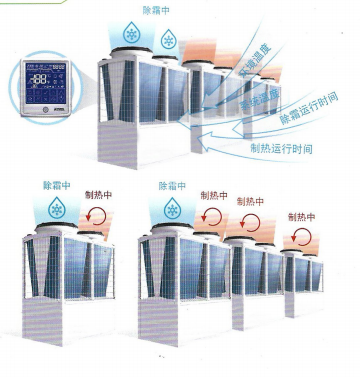

压缩机均衡运转: 多重防冻保护: |

|

四、配置可靠

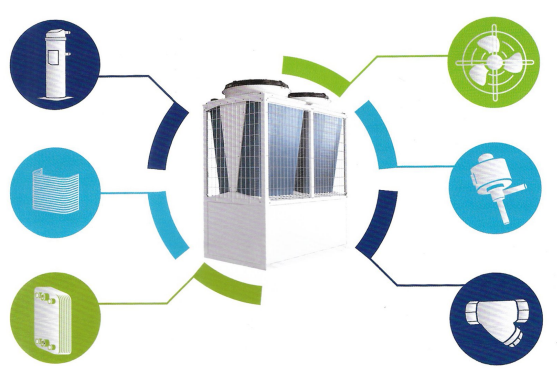

| 高效R410A全封闭压缩机 |

|

空气侧换热器 |

|

定制型风扇组件 |

|

| 低压腔结构设计,曲轴箱处于较低温区域,电机被低温回气制冷,延长电机寿命。 |

独特“U”型换热器,多面换热优化风场设计;标配亲水铝箔翅片:抗氧化抗腐蚀能力强。 | 大直径圆角轴流风叶导风圈,导风罩一体化设计, Ip55双速电机,室外安装防护性强。 |

| 高效不锈钢板式换热器 |

|

电子膨胀阀 |

|

过滤器&水流并关 |

|

| 不锈钢结构,稳定可靠;非对称的流道设计,降低了水侧压降,同时带.来卓越的防冻性能。 |

采用480步高精度调节的电子能胀阀对制冷剂流量进行智能自适应调节,确保制冷剂流量精确,系统运行压力和温度处于最佳状态。 | 单模块标配全铜高效过滤杜绝直径过大颗粒进入主机,防止脏堵;单模块内置水流开关,防止系统水流量过小引发机组冻裂风险, |

| 多重选配 | 挡板&栅格 弹簧减震器 |

降噪组件 标准集控器 |

view i集控器 SC- Equip组件(转换BAchet)弹簧减震器 |

五、舒适宁静

XYR系列机组运行噪音低,标准出厂噪音最低低至65dB(A),为客户提供宁静的工作与生活环境:

| 单模块双风机设计: 有效分担单个风机的风量,降低单个风机的运行噪音; |

|

| 标配双速风机: 根据负荷变化调节风机转速来降低机组运行噪音;静音模式:选择静音模式功能,风机低速运转噪音可以下降3~5dB(A);定制型风扇组件:风扇电机、导风罩、导风圈一体化设计减小排风阻力,修正排风方向,降低风机运转噪音; |

|

多种降噪选项: 可以选配机组挡板降低关键部件运转噪音、选配消音棉等降噪组件,噪音还可以更低: |

|

新一代微电脑控制中心: 实时监控机组关键部件运行状态,优化机组运行逻辑,有效降低机组启停噪音。 |

六、运行可靠

| 宽运行环境温度范围: 全年-15°C~48°C的稳定运行环境温度适应全国大部分地区的气候。无论在严寒还是酷署, XYAE-X系列机组均能为室内提供稳定的热、冷水。 XYR系列机组每个型号均在生命周期加速实验室(HALTTesting Lab)中进行测试,该测试可模拟机组在各种气象条件(风、雪、雨、霜等)现场遇到的各种极端恶劣工况,在2 ~ 4周的时间内模拟整年工况来保证机组在现场运行的可靠性。 |

|

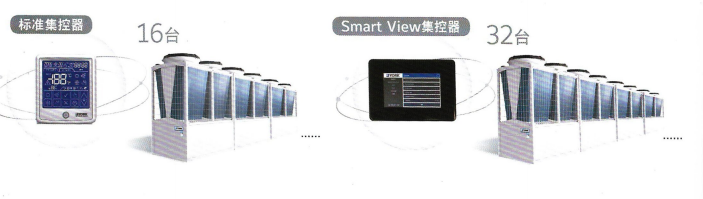

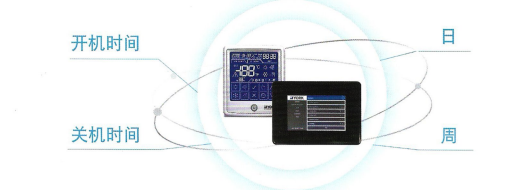

七、只能控制

本地控制与通讯

提供2种触摸屏控制器可选

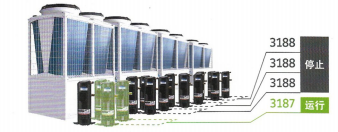

标准集控器:小巧美观, 友好互动的液晶触摸屏设计,可拼接16台机组,空调系统制冷量范围可扩展至2080kW;

Smart View集控器: 全触摸7寸彩屏界面,参数显示更多更全;多级别权限设置保障空调系统安全运行;支持USB软件升级,维 护方便;可拼接32台机组,空调系统制冷量范围可扩展至4160kW.

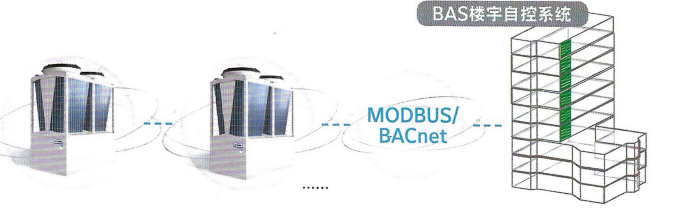

远程控制与通讯

自带RS-485接口 , 开放MODBUS/BAcnet协议 , 轻松接入楼宇自控系统。

联动控制

一次泵变流量系统: XYR系列机组可以同时连接两个集控器,同时满足两组不同管理方的控制.需求; XYR系列机组自带多种远程控制干接点,可以实现远程开关、远程热冷模式切换、与末端温控器开关联动、远程报警等功能,应用灵活。 |

|

日程控制

用户可自由设置日 、周 ( 节假日除外 ) 等开关机时间。

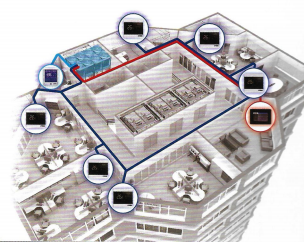

八、应用灵活

安装灵活

安装位置灵活:

无需专用机房,无需冷却塔、冷却管路以及冷却水泵,可以安一装于地面、屋顶、设备层等开阔空间,安装位置自由;运输就位灵活:

突破传统外形结构,单模块同冷量尺寸更小,重量更轻,可用铲车和货梯进行移动和搬运,方便现场运输与就位;

拼接方式灵活:

多台模块安装时,可选择长度或者宽度方向拼接,也可以根据用户的需求采取其他方式进行排布。

运行灵活

冷媒系统互为备用:单个模块双冷媒系统完全独立运行,其中--套系统发生故障不影响另外-套冷媒系统正常运转,单机运行更可靠;模块之间互为备用:

多台机组模块化拼接运行,单台机组的维护和保养不影响其他模块的正常运行。

配置灵活

配置灵活:

XYRAE065.XYRAE100X和XYRAE130X三个型号可实现模块混拼,系统选型配置更灵活;

投资 灵活:

可分批投资,随时扩充模块数来满足业主后期投资的要求。

九、低碳环保

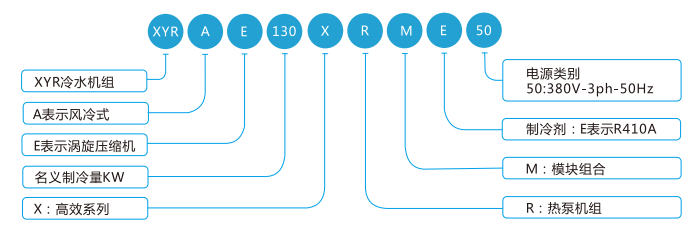

十、产品命名

| 机组型号 | XYAE065XRME | XYAE100XRME | XYAE130XRME | ||

| 名义制冷量 | KW | 65.0 | 130 | ||

| 名义制热量 | KW | 100.7 | 131.9 | ||

| 名义制冷输入功率 | KW | 204 | 292 | 393 | |

| 名义制热输入功率 | KW | 200 | 300 | 428 | |

| 部分负荷性能系数 | 4.30 | 4.34 | 4.34 | ||

| 电源 | V/ph/Hz | 380/3/50 | |||

| 制冷剂 | R410A | ||||

| 压缩机 | 类型 | 涡旋 | |||

| 数量 | 台 | 2 | 3 | 4 | |

| 风扇电机 | 风机数量 | 台 | 2 | 2 | 2 |

| 风量 | m3/h | 11000x2 | 12500+ 21500 | 21500x2 | |

| 电机功率 | KW | 0 . 9x2 | 0 . 87+ 1 . 65 | 1 . 65x2 | |

| 机外静压 | pa | 30 | |||

| 水侧换热器 | 形式 | 钎焊板式换热器 | |||

| 名义水流量 | m /h | 11.2 | 17.2 | 22.4 | |

| 机组水压降 | kpa | ||||

| 进出水管连接尺寸 | DN50 | DN65 | DN65 | ||

| 水管连接方式 | 螺纹 | 卡箍 | 卡箍 | ||

| 外形尺寸 | 长*宽*高 | m m | 1650x760x1700 | 2250x1200x2420 | 2250x1200x2420 |

| 机组重量 | 运行重量 | kg | 503 | 864 | 982 |

| 电气规格 | 额定电流 ( 制冷/制热 ) | A | 37 4/36 7 | 55/58 | 74/80 |

| 最大电流 | A | 52 | 85 | 112 | |

| 噪音 | dB(A) | 65 | 68 | ||

注:

1.因本公司产品更新而致型号规格 、参数变更, 恕不另行通知; .

2额定制冷能力测试工况:室外环境温度35 ° C (干球) ,主机制冷进/出水温度12 ° C/7 ° C;

3.额定制热能力测试工况:室外环境温度7 ° C (干球)/6 ° C (湿球), 制热进/出水温度40 ° C/45 ° C; 4.标示噪音值为新雅半消音室实验值, 根 据不同的安装条件会有所差异。

Product Inquiry

*Note: Please fill in the information accurately and keep the communication open. We will contact you as soon as possible.