洁净手术室用空气调节机组

Product Category:

Keywords:

Clean air conditioning unit for operating room

air

一、型号说明

WJKYH2-4B |

3.2 |

H |

4 |

B |

新雅组合式空调机组 |

名义风量( x10 m 3/h |

洁净空调调节机组(直膨式 ) |

盘管总排数 |

方案代码( B 、 BT 、 E 、 ET) |

|

BT- 循环机组, 30# 铝合金框架结构 |

E -新风机组 , 50# 铝合金框架结构

|

H-直膨式洁净空气调节机组

|

HZ -冷水式洁净空气调节机组

|

|

WJKYH2-4B

|

WJKYH2-10E

|

WJKYH2-13ET

|

|

洁净手术室用空调机组,名义风量

200m3/h, 盘管总排数4排,50#铝

合 金 框 架 结 构 , 箱 板 厚 度

50mm。适用于洁净手术室、生物

安全实验室等场合使,用的新风经

预处理后的循环机组,洁净走廊、

污物走廊、中心供应室等场合使用

的自取新风的循环机组。

|

洁净手术窒用空调机组,名义风量

3200 m /h,排管总排数10排,50#

铝合金框架结构,箱板厚度

50mm。适用于洁净手术室、生物

安全实验室、医院、药厂的动物房

等场合使用的新风预处理机组。用

的自取新风的循环机组。

|

洁净手术室用空调机组,名义风量

3200m /h,排管总数13排,30#铝

合金框架结构,箱板厚度

30mm,

带

深度除湿装置。适用于洁净手术

室、生物安全实验室、医院、药厂

的动物房等场合使用的新风预处理

机组,尤其使用高温高湿地区。

|

机组内表面边角设计为圆弧过渡以便清洁,缝隙采用无硅密封胶;表冷段位于正压段,不设挡水板,干式接水盘保证排水顺畅,避免积水:配置紫外线

杀菌灯;接水盘选用抑菌型材质,可持续杀菌,杀菌效率达99.99%以上;箱体内壁板可选用抑菌材质,以达到更佳的抗菌效果。

对于有严格温湿度要求的机组电加热器可采用多级等比分配或1:2:4差级分配方式以满足温升的微调精度加湿器可选择干蒸汽加湿器,电极式加湿器或电热式加湿器。通过先进的自动控制、高精度的传感器配置及严格控制的冷热源动力,AAHM-H2系列机组可以实现温湿度的高精度控制(最高可达温度士0.5℃湿度土2%)。

该系列产品有初中高效三级过滤器可选过滤器等级最高可达H13。同时提供纤维活性碳复合过滤、Ti02杀菌器、紫外杀菌器等,有效进行除尘杀菌,确保室内空气新鲜健康多种过滤装置。源动力,AAHM-H2系列机组可以实现温湿度的高精度控制(最高可达温度士05℃温度土2%)。

|

|

|

|

超强除 湿 |

智能 化 |

模块式 |

|

|

|

|

|

新风旁通

|

无需冷源

|

自带电气

控制系统

|

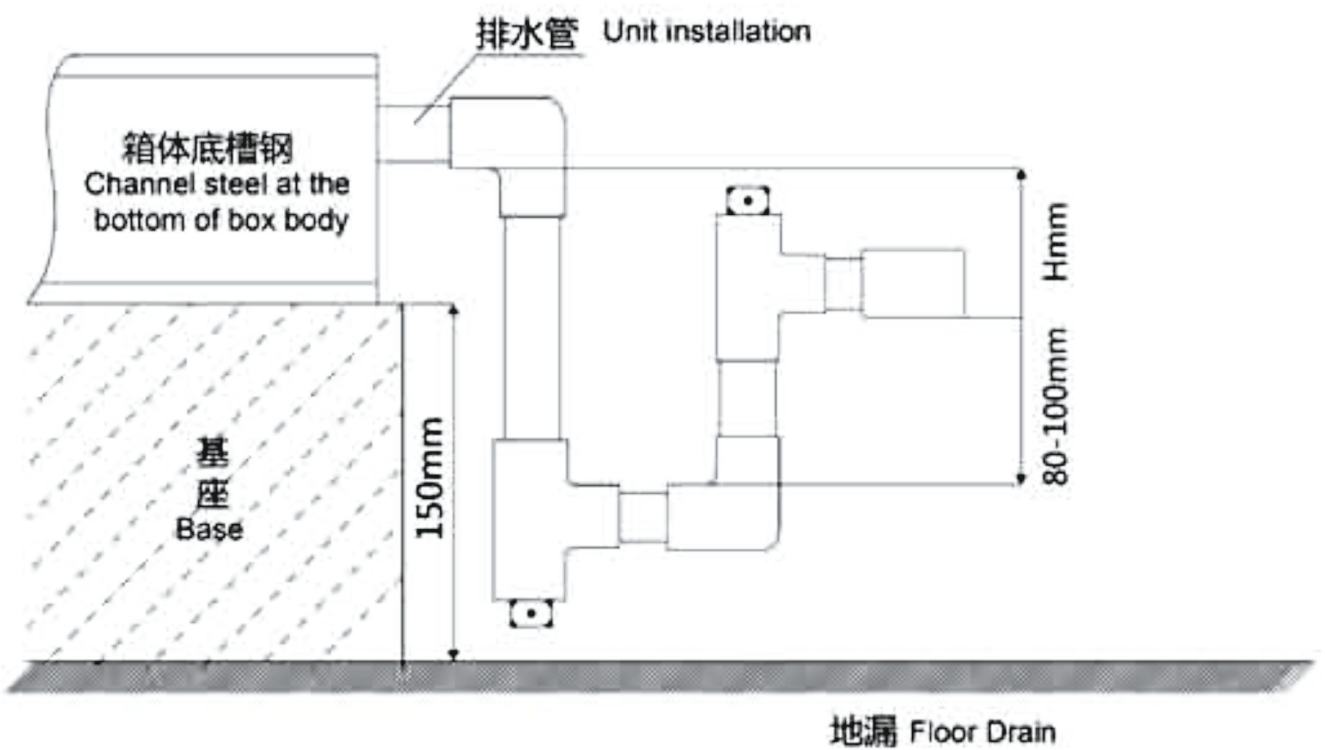

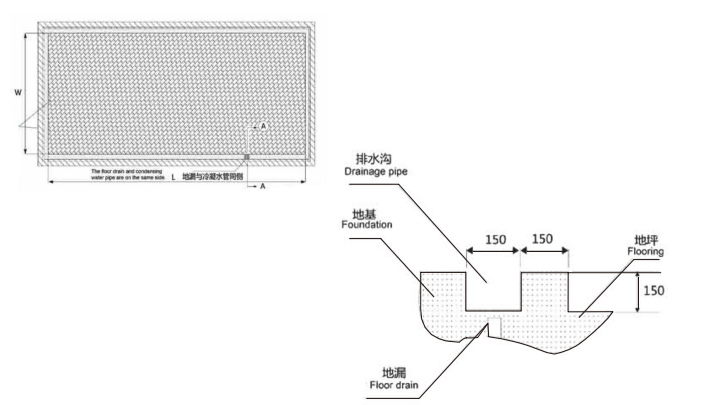

除吊顶机组外,所有结构形式的空调机组都应安装在一个水平的基础之上。机组四周,尤其是机组配管和风机与电机的检修门一侧应留有充分空间,以便于机组的日常检视和定期维护。凝结水出水口必须先接驳一个“U”形排放管,然后才与外管联接。在接驳盘的进出水管时,应平衡用力,不要用力过猛,以免损坏盘管。空调机组的电机应接在有过载保护的电源上,并有接地保护。空调机组与外接风管间应采用柔性连接以避免振动的传递。对直膨式机组,室内机与室外机的连接盘应尽量短,并减少高度差和弯头

数量。室外机安装需有足够的检修和散热空间。

六、机组使用

每次运行机组之前,都应检查其水路和风道的各阀门,井使之处于正常的操作状态。

应定期检查风机和电机等运动件的联接、运行和传动情况,并及时调整。初效过滤器应根据污垢程度用清水或清洗剂清洗,清洗的频度视使用的环境而定。中效过滤器当其阻力,上升到初始阻力的两倍时,应予以清洗或更换。机组在冬季不运行时,应将盘管中的水放掉,机组在冬季继续运行时,短暂停机,则必须保持盘管内水连续流动,并关闭新风阀,以免冻坏盘管,长期停机则需将盘管中的水放掉。冷水和热水应为清洁的软化水。机组每运行两年,应以化学方法清除盘管内的水垢,并用压缩空气或水清理翅片

表面的污垢。必须保证蒸汽加湿器在风机停止前关闭蒸汽阀。必须保证风机开启后,才开启电加热风机停止前5分钟,关闭电加热。

Product Inquiry

*Note: Please fill in the information accurately and keep the communication open. We will contact you as soon as possible.